Chances are, if you’re in an industry that uses packaging machinery, you already know it. But if you’re a small business, or are looking for a way to optimize your packaging process, you may not be aware that there are options available to you at a cost that might fit your budget better than brand new machines. Many different industries can benefit from used packaging machines—can yours?

What Industries Benefit from Packaging Machines?

Other industries that use packaging machines include:

• Automotive

• Cosmetics

• Toys

• Retail

These are just a few of the industries that can use packaging machines to advance their business and productivity. If you’re interested in optimizing your packaging line, but are working with a tight budget, buying used packaging machinery is a great way to do so. We offer high quality machines that will fit into your budget and are restored to be fully functional for years to come.

What Kind of Machines Can These Businesses Use?

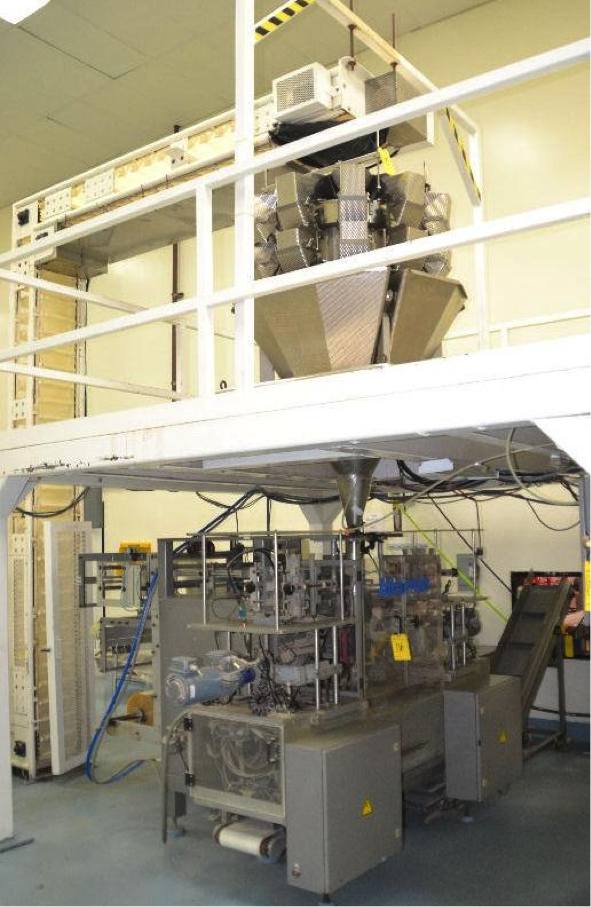

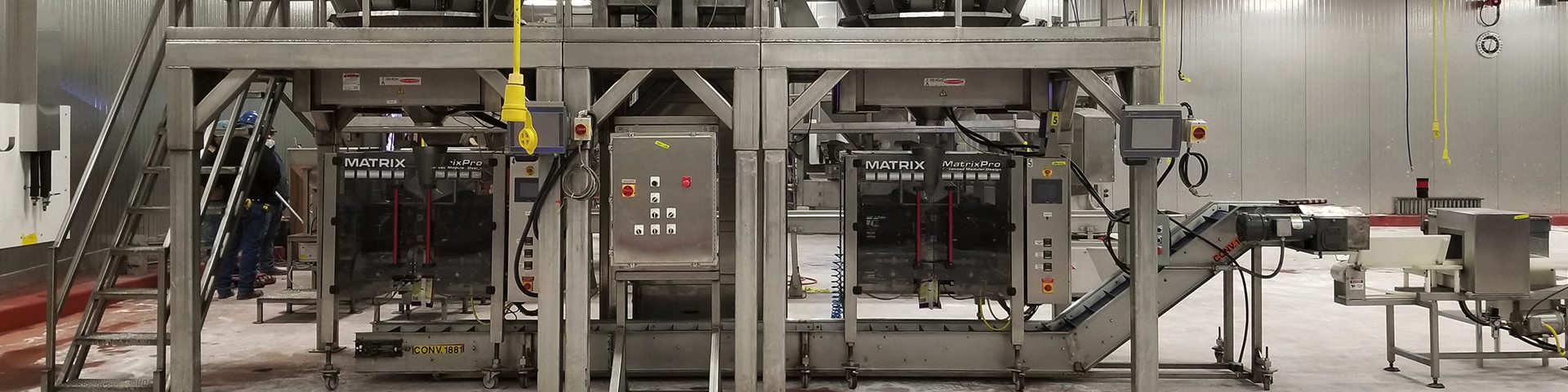

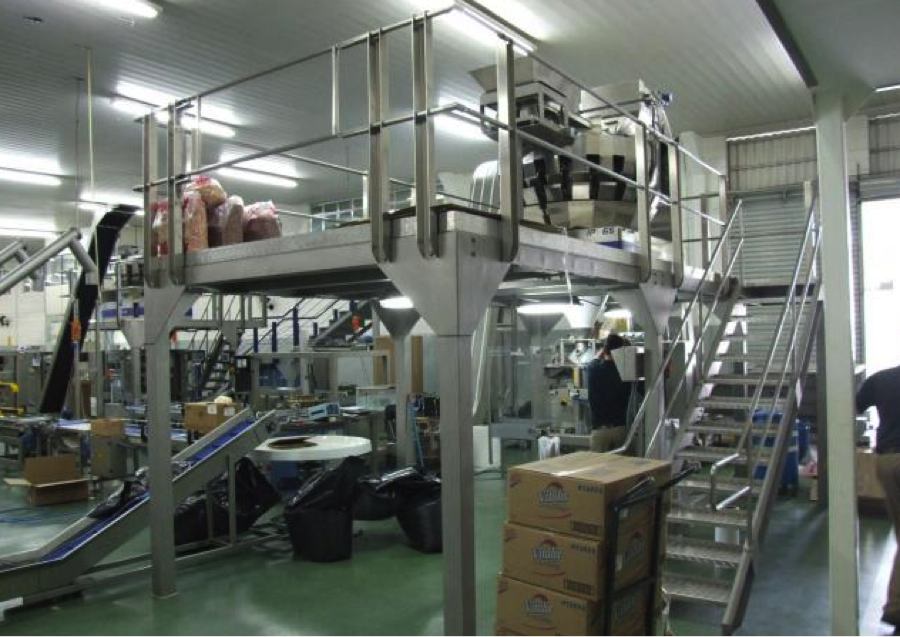

Within these industries, different companies can benefit from different types of packaging machines. For instance, combination weighers can be used for weighing out multiple bags of product quickly and easily, which is ideal for the food industry. Shrink bundling machinery, including form fill and seal machines, is ideal for packages that need to be airtight, or need to be sealed with no airspace between the package and product, such as automotive parts. Many industries can benefit from using conveyers, as well – these help speed up the packaging process for virtually any item you’re packaging. No matter what sort of packaging machine you’re interested in, buying refurbished is a great way to build up your line without breaking the bank.

For more information about the different types of machines that High Performance Packaging offers, contact us today—we’re happy to help you find whatever you need to make your business work better.

Packaging machinery is complicated—there’s no way around that. Purchasing new machinery has the potential to slow down your production, particularly if your employees are not well versed in how to use it. Training can take some time, but if you don’t know how to train the employees on the new machinery, you may be stuck. Thankfully, when you purchase used packaging equipment from High Performance Packaging, you get the additional benefit of our training programs.

Packaging machinery is complicated—there’s no way around that. Purchasing new machinery has the potential to slow down your production, particularly if your employees are not well versed in how to use it. Training can take some time, but if you don’t know how to train the employees on the new machinery, you may be stuck. Thankfully, when you purchase used packaging equipment from High Performance Packaging, you get the additional benefit of our training programs.