When your company is selling and shipping food, packaging is one of the most important parts of your product. Shipping food when its packaging has been damaged can cause health problems for those who purchase it—and this can mean expensive legal trouble for your company.

The packaging machine that is used also makes a difference in the quality of the product and the integrity of the packaging. There are several different types of food packaging machines that are responsible for filling and sealing everything that you see on store shelves from cereal to flour and juice.

Here is an overview of the two basic types of machinery used in many food packaging designs.

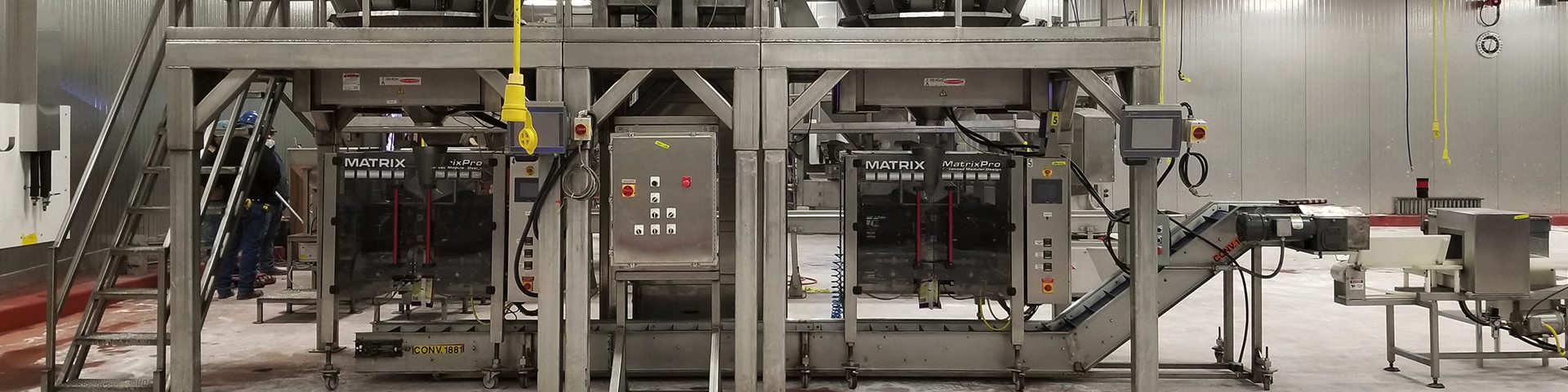

VFFS (Vertical Form Fill Seal)

VFFS equipment allows for product to be fed into a packaging design to a certain predetermined level after which, it will seal the packaging. Regardless of your sealing needs, many brands of these machines have changeover parts or settings that allows for multiple settings to be managed by a manufacturing facility. If you’ve ever opened a bag of potato chips, chances are it was filled and sealed with VFFS equipment. The machinery is a staple in the food industry for dry goods, frozen foods, coffees, teas and more.

HFFS (Horizontal Form Fill Seal)

These machines are used in a variety of industries, but in the food industry, they are particularly useful for packaging horizontally sealed products. These items could include cookies, hamburgers and other foods that need to be thermoformed (heating plastic to meet the needs of the packaging design). These machines are also useful in creating blister packs for spices and other dry goods packaged in single serving trays.

Benefits of Used Equipment

Depending on your needs, there is a VFFS or HFFS machine out there to fill them. Buy used packaging equipment to save money while increasing your bottom line quickly. Used equipment that has been refurbished will have passed rigorous inspections to ensure the quality is on the level of the best machinery in the industry. A few companies, like High Performance Packaging, will also offer a competitive maintenance program to ensure the quality of your purchase.

Whatever your package machinery needs, High Performance Packaging can help. Our experts can assist you picking the perfect equipment for your food product. Contact us today to learn more.