Like other pieces of packaging equipment, vertical form fill seal (VFFS) machines require occasional preventative maintenance to avoid breakdowns. If your VFFS machine malfunctions or operates inefficiently, it’s important for packaging line operators to accurately identify and address the issue before it can result in avoidable downtime. There are many components that keep VFFS machines functioning the way they should, which can make diagnosing an issue difficult. Here are some common sealing issues, along with possible causes, that can give you an idea of how to troubleshoot VFFS packaging machines. In cases where issues are more extensive, packaging lines may benefit from replacement new or used packaging machines, which we can provide with a wide selection of reliable equipment.

Poor Seal Integrity

One problem that can arise is a lack of seal integrity. VFFS machines should be able to form seals that consistently meet industry standards. When these seals aren’t as tight as they should be, there are several steps that operators should take to fix the issue:

- Make sure sealing jaws are parallel, which you can test by sealing on a sheet of A4 paper and examining the trace.

- Keep temperature settings consistent, and ensure that they apply to the sealing jaws. If you need to increase or decrease the temperature, adjust both time and pressure as well.

- Clean sealing tools that look even mildly dirty.

- If a machine has gusset areas, leakage may be present, in which case you should check the gusset area pressure.

- If contamination is too prevalent to allow for proper cleaning, you may need to replace the sealing components.

Seal/Peel Weaknesses

Another potential problem is a weak seal or peel. The most common solution for both is to adjust temperatures to the correct settings. However, problems with seal strength may involve the thickness of the base film and the specific type of seal layer. Normally, thicker base films result in stronger seals, but at the same time, thicker materials allow for a shorter temperature range.

Hot-Tack Problems

If the packaging material at the bottom seal cannot hold the packaged contents while heated, there are several ways you can fix this:

- You may need to increase the temperature of the sealing area to create a stronger seal. Operators should perform regular checks to make sure that the temperature settings are where they need to be.

- If necessary, cooling air blasts may help increase hot-tack strength.

- If a lack of pressure is the problem, increase the pressure of the sealing jaws.

- Replace the current sealant design with a new one if needed.

Of course, there are many other types of problems that can occur with VFFS equipment. Performing regular preventative maintenance checks will allow operators to determine which type of issue the packaging line is experiencing, and subsequently make it easier to troubleshoot VFFS packaging machines and other machinery. If you require the expertise of experienced technicians, packaging companies like High Performance Packaging can send packaging machine experts to your facility who can identify technical problems and also further train your operators.

Replacing VFFS Machinery

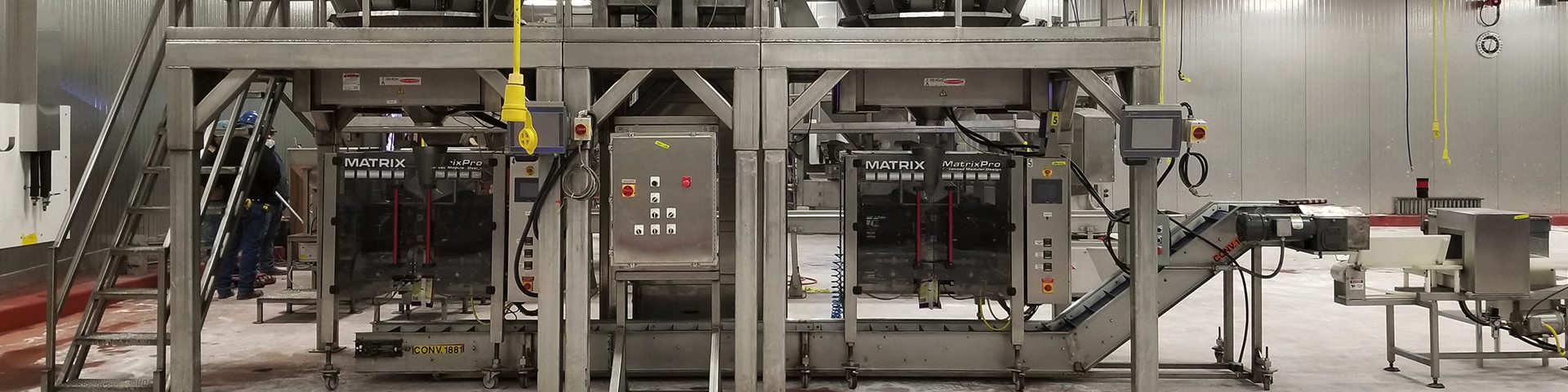

If your VFFS machines are damaged beyond repair or won’t be able to perform to your project specifications, you may need to replace the equipment. In addition to assistance for troubleshooting VFFS equipment, we offer a selection of reliable used VFFS machines and much more. You can find some of the best packaging equipment available anywhere when you browse our full inventory of products, with VFFS machinery from some of the top brands, and we also carry many other top-quality packaging machines, including complete form fill and seal systems.

Connect with High Performance Packaging for All of Your VFFS Machine Needs Today

We can make sure you get everything you need to keep your packaging systems operating optimally. You won’t need to worry about inefficiency or a lack of productivity with our preventative maintenance services, along with the other services we offer. You’ll see a difference when you work with High Performance Packaging for all of your VFFS machinery needs. If you would like to benefit from our maintenance services or learn more about our VFFS equipment, contact us today.