Cryovac is the food packaging division of Sealed Air, a company that’s responsible for many types of food and non-food care products. One of the main types of packaging machines in their product line is liquid filling equipment, which High Performance Packaging carries. They also have a wide range of other kinds of equipment that can provide airtight packaging for many types of food products. The quality of Cryovac packaging machines makes it ideal for recirculation.

Utilize Cryovac Packaging Machines for Many Products

Sealed Air’s Cryovac packaging machines can seal several different types of food packages, increasing operational efficiency, improving food safety, and extending shelf life. The various products that this machine packages include:

- Fresh red meat

- Smoked and processed meat

- Poultry

- Dairy liquids

- Dairy solids

- Fluids and pumpables

- Fish and seafood

- Convenience foods and ready meals

- Bakery and snack foods

- Produce

There are multiple purposes for Cryovac machinery in production lines. They are used for vacuum packing, hermetic sealing, and liquid filling, and are capable of maintaining optimum efficiency in fast-paced facilities. This equipment uses the latest technology in the industry to provide top quality packaging for every product.

Integrating Used Cryovac Packaging Machinery in Your Facility

The durability of Cryovac equipment makes it useful for many years in production lines. Their heavy-duty design helps them hold up through significant use, and if packaging line managers need to modify their facilities by removing Cryovac equipment, they can sell it to a used packaging machine reseller like High Performance Packaging. There are several reasons you should purchase used Cryovac packaging machinery over newer models and implement them in your production line.

The main benefit you’ll experience with used models is the lower cost. Even if a Cryovac machine has been used for many years in multiple facilities, a good packaging company will restore it to working condition prior to reselling, and customers won’t experience any compromise in quality once it’s installed. Used Cryovac machines can bring the same level of efficiency and productivity as their new counterparts.

Another benefit of buying used Cryovac packaging machinery is the additional services that certain companies offer along with the equipment itself. Companies like High Performance Packaging offer operator training, preventative maintenance, and performance improvement services. These services can help ensure that your facility is operating at maximum productivity and efficiency, with fully functioning machinery and knowledgeable operators behind it.

Buying Cryovac Equipment from High Performance Packaging

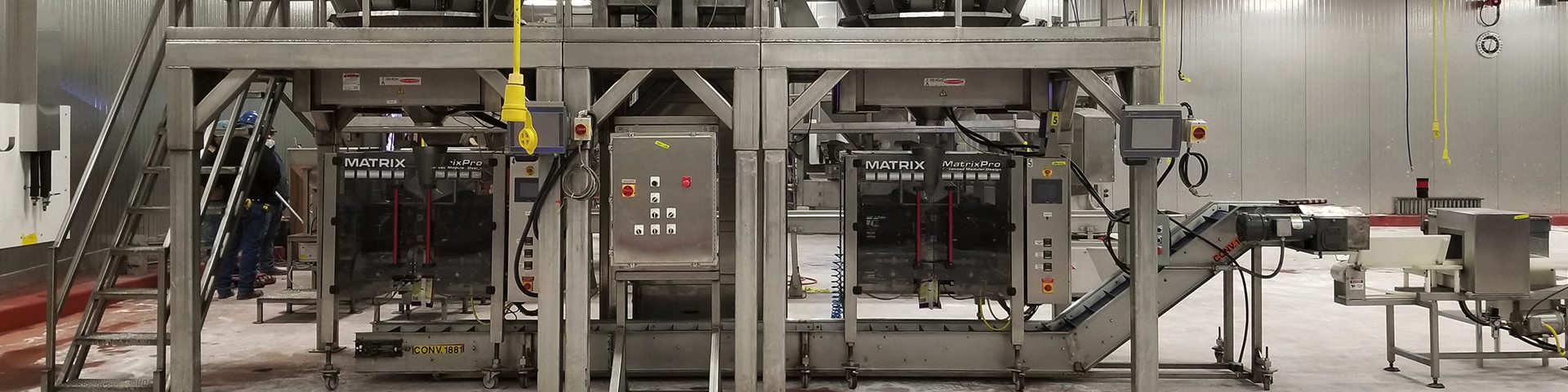

Cryovac liquid filling machines are among the many different kinds of used packaging equipment available at High Performance Packaging. These liquid fillers are useful for many types of liquid filling applications, and we have packaging equipment for many other applications. We carry vertical and horizontal form, fill and seal packaging equipment, vacuum sealers, conveyors, case packers, case sealers, and much more. Some of the top brands appearing in our inventory include Hayssen, Yamato, Ishida, Matrix, Markem-Imaje, and Combi.

For more information about Cryovac equipment and other machinery in our inventory, contact us today. We’ll also provide a free quote.