Source: cargillfoods.com

Edible oil and fat products require reliable filling machinery during the packaging process, along with other packaging machinery. High Performance Packaging carries a range of used auger and volumetric fillers that are in working condition and ready for use in these production lines. We have all the used oil and fat filling equipment that your facility needs.

With a combination of our machinery installed in your facility, you can benefit from equipment that offers both reliability and affordability.

Volumetric and Auger Filling Systems

Oils and fats utilize many different types of packaging, depending on the specific type of product. Oils made with soy, corn, rapeseed, sunflower, olives, and fatty food products such as margarines and spreads each have different filling requirements. The right selection of oil and fat fillers can sufficiently fill many types of containers with these products.

Other Oil and Fat Packaging Machines

Apart from used oil and fat filling equipment, High Performance Packaging offers used conveyors, wrappers, and inspection equipment to finalize the packaging process for these products. Reliable metal detectors and X-ray inspection machinery can properly assess product packaging to detect potential contamination from metal or other types of particles that can sometimes end up inside final packaging contents. Flow and shrink wrappers can provide top-quality wrapping for many types of containers at the end of the production line.

Why Buy Used Oil and Fat Packaging Machines?

While purchasing new oil and fat fillers and other types of equipment, there are certain benefits that come with purchasing used machines. A company like High Performance Packaging can help make sure that there isn’t a compromise in quality with used equipment, inspecting each piece of machinery before recirculation. Reliable packaging machine resellers offer top brands of used equipment to for quality assurance, while allowing customers to utilize this equipment at lower prices.

Another benefit that can come with used oil and fat filling equipment is a host of services that production line managers may otherwise remain without. Some of the services certain companies offer may include operator training, performance improvement, OEE programs, installation, preventative maintenance, and line start-ups to simplify the launch of a new production line. These services can add many years to a packaging facility, giving equipment and staff the tools they need to thrive in many types of applications.

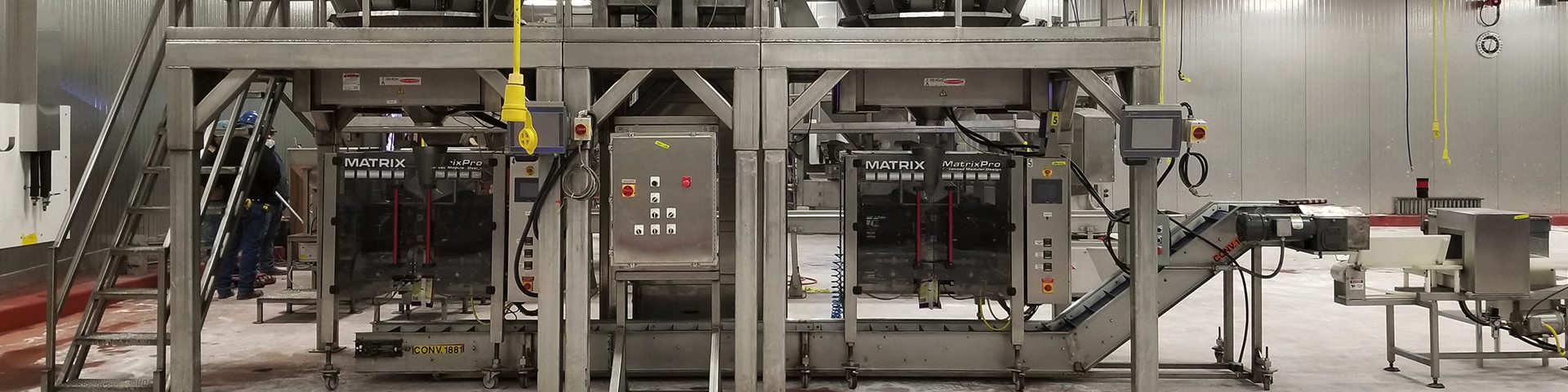

Want additional information and a free quote for used oil and fat packaging machines available at High Performance Packaging? Contact us at any time and we’ll be happy to discuss our products and services. We also carry equipment for many other applications involving food and nonfood item packaging. Our inventory includes state-of-the-art used packaging equipment from top manufacturers in the packaging industry, including Yamato, Ishida, Hayssen, Kliklok-Woodman, and Matrix, among many other trusted brands. We can assist with machine selection and provide services that can significantly help with the upkeep of your facility. We are dedicated to helping customers get the most out of their production lines on a long-term basis.