If you’re in the market for a checkweigher for your packaging line, you’ve likely done some research to learn more about recommended brands to look for. If you’re on a tight budget, however, you may feel like finding the ideal checkweigher is out of reach.

Used Checkweighers

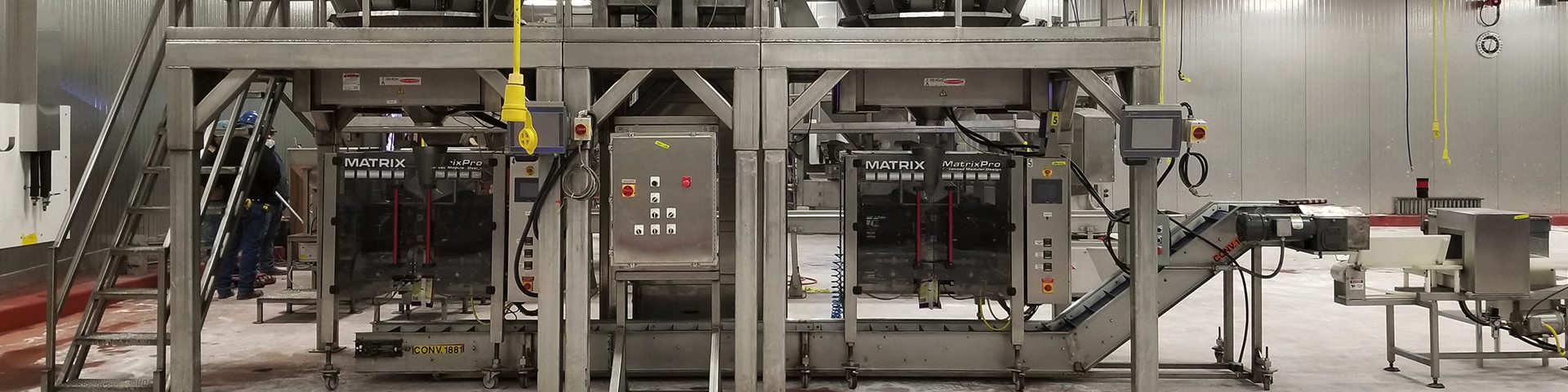

That’s where we come in—at High Performance Packaging, we know that not everyone can afford the high cost for brand new equipment, and that’s why we’re proud to offer used machinery, including checkweighers, from trusted names at competitive prices.

Some of the checkweighers we offer are from brands like:

Finding the Best Checkweighers

Checkweighers from these and our other brands are known for being long-lasting and reliable pieces of machinery, and are therefore a worthwhile investment. Because we believe that very company deserves to use equipment that will serve their business well for many years, without spending more than they can afford. For that reason, we strive to stock the best used equipment we can.

When you’re purchasing a check weigher, you want to make sure that it will be able to accurately check the weight of your packaged goods. If the scales are inaccurate, you could find yourself losing money over inaccurate, inconsistent packaging.

Conveyor Belts

An automatic check weigher will incorporate a series of conveyor belts and can weigh 500 or more items per minute, depending on the carton size and accuracy requirements (the amount of wiggle room for specific weights).

Checkweigher Equipment

They can also be designed to incorporate additional checking devices, such as metal detectors or X-ray machines to ensure optimal accuracy.

For more information about these and other used equipment that we currently offer, or to learn more about the brands we sell, contact High Performance Packaging today.